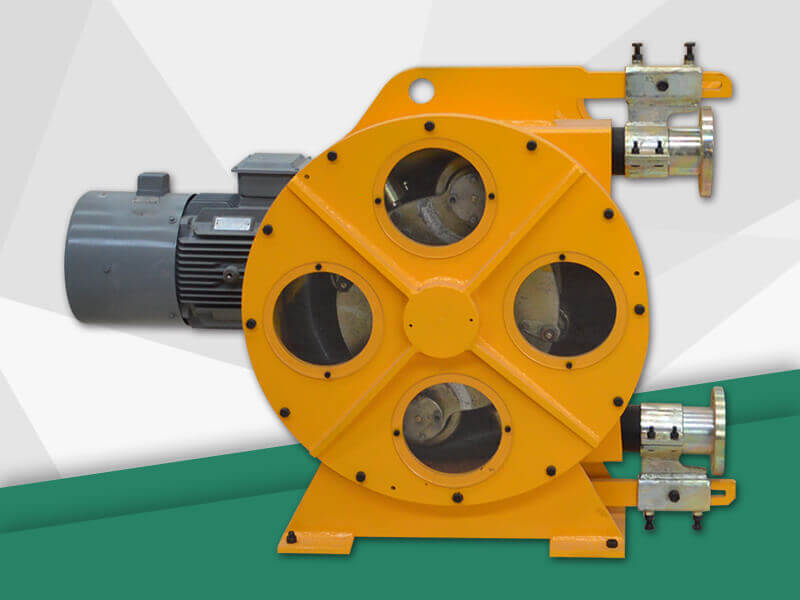

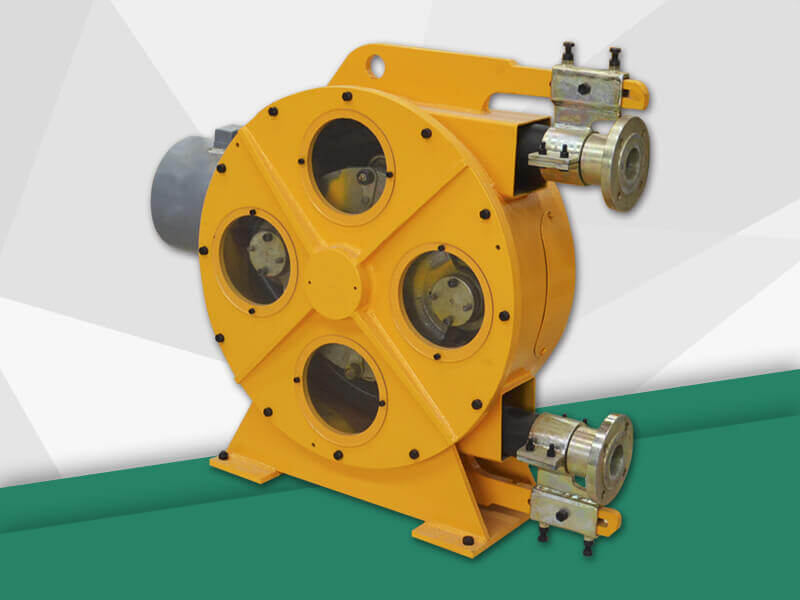

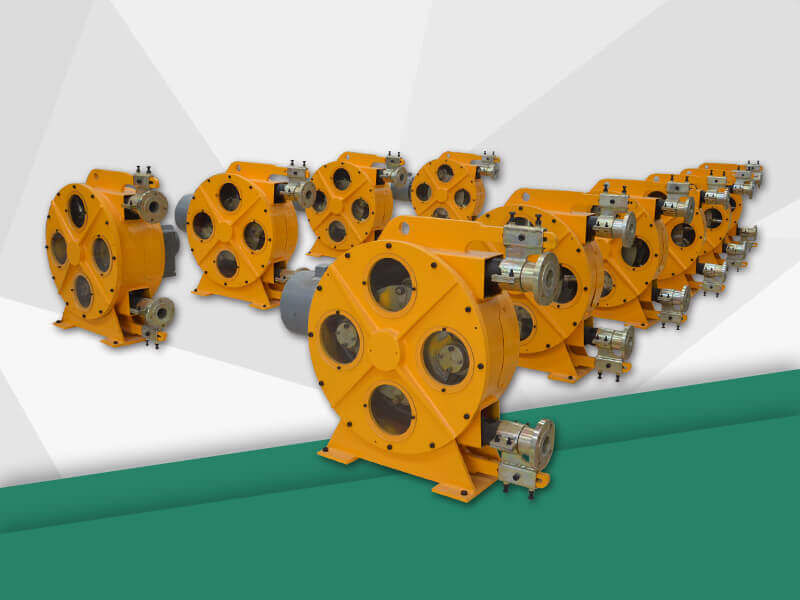

GH65-680B industrial corrosion resistant peristaltic hose pumps are used in a wide range of applications in the chemical industry, such as pumping paints, coatings and pigments for paint plants; transporting or discharging fiber liquids, dyes or waste water for textile mills; pumping or metering of corrosive and hazardous materials in pharmaceutical plants.

GH65-680B industrial corrosion resistant peristaltic hose pump is a kind of peristaltic pump. An elastomeric tube is squeezed along a length by rollers that push the fluid contained within. The tube’s restitution after squeezing produces a vacuum that draws fluid continuously into the tube. This creates a gentle pumping action that doesn’t cause any damage to the product. Contaminations are avoided because the fluid is contained within the tube.

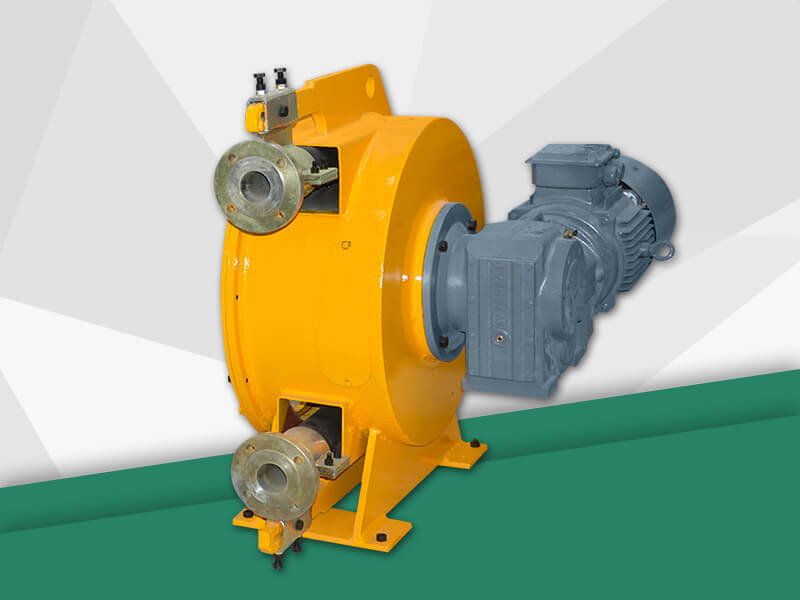

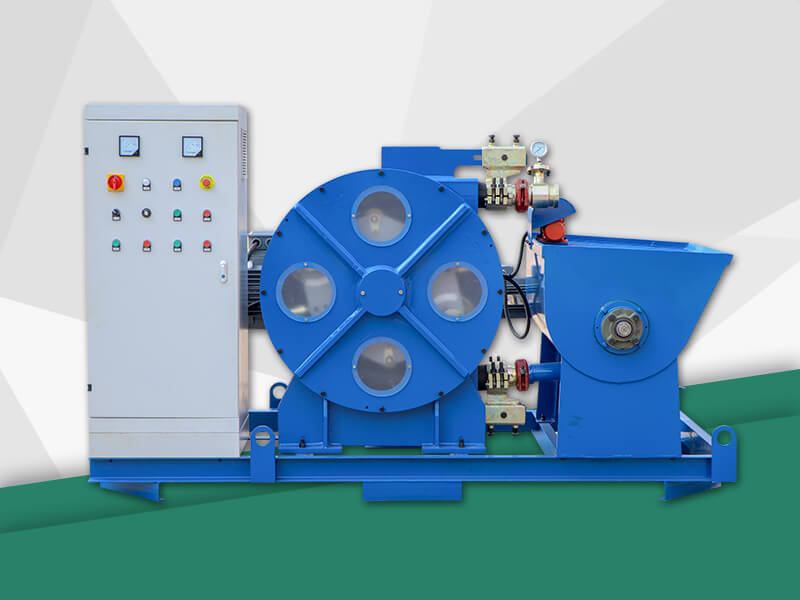

GH65-680B industrial corrosion resistant peristaltic hose pump is a new industrial hose pump developed by advanced technology. The pump has no seal, no leakage, strong self-priming ability, simple structure, and convenient operation and maintenance. Suitable for conveying various viscosity, density, corrosive and abrasive substances. It can be used in petroleum, chemical, water treatment, mining, gold smelting, medicine, paper, ceramics, and other industries.

GH65-680B industrial corrosion resistant peristaltic hose pump products comply with national and international standards. GH65-680B industrial corrosion resistant peristaltic hose pump has stable performance, good sealing performance, easy operation, no water cooling, beautiful and durable. They are suitable for transporting a variety of chemical media with different viscosities and temperatures and are therefore widely used in many fields.

1. Gold smelting industry: gold pulp and tailings transportation;

2. Chemical industry: acid, alkali, phosphate and titanium dioxide phosphate, titanium dioxide (met titanate) slurry, crystallization liquid, suspension, latex, resin, slime and various liquids;

3. Drilling mud in the petroleum industry: transportation of crude oil and transportation of organic solvents and fuels such as gasoline and kerosene;

4. Water treatment: sludge, lime slurry, added chemicals, sampled water, sediment transport;

5. Mining, metallurgical industry: such as gold mining in filling materials, iron oxide scale, flue mud treatment of thick slurry, underground passage drainage, adsorbents, mortar and mortar;

6. Pharmaceutical industry: transportation of liquid materials;

7. Food industry: food and beverage transportation;

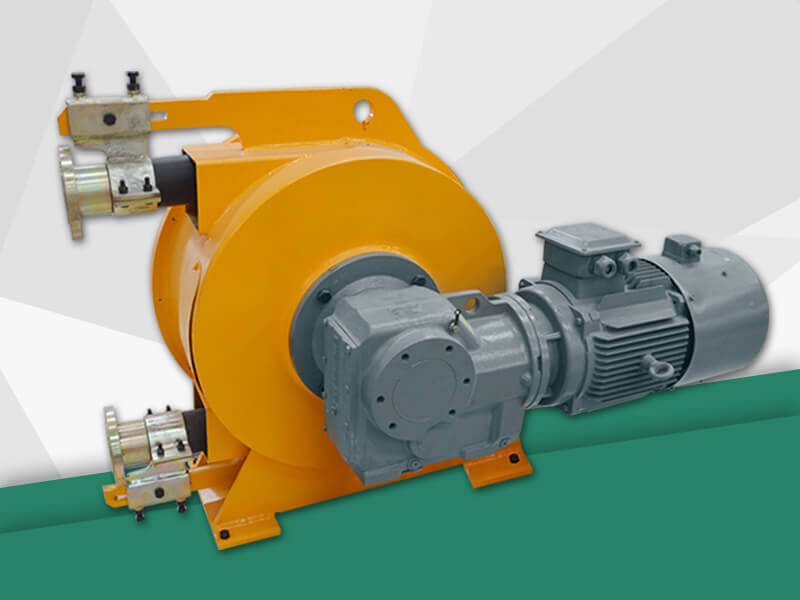

GH65-680B industrial corrosion resistant peristaltic hose pump used for mine is suitable for pumping slurry, mortar, oil based, slurry, flammable, explosive and certain high viscosity fluids in the mining industry. It has a strong self-reinforcing capability, high flow and easy operation.

In addition to this, GH65-680B industrial corrosion resistant peristaltic hose pump used for mines have many features superior to other types of pumps:

1. Reversibility

2. No seals, no valves

3. Abrasion resistance

4. Corrosion-resistant

5. Self priming with high suction

6. With 1% repeat precision

7. Easy to clean

8. Dry-running without damage

9. Peristaltic tube is the only consumption part

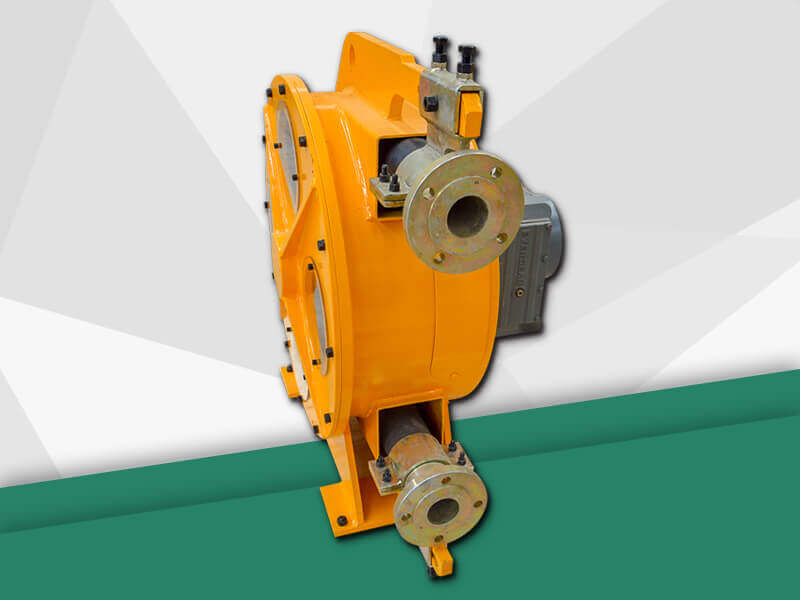

|

Type |

GH65-680B |

|

Output |

8m3/h |

|

Rotation |

33RPM |

|

Squeeze hose ID |

65mm |

|

Max. pressure |

1.0Mpa |

|

Voltage |

3 phase, 380V, 50HZ |

|

Power |

7.5KW |

-

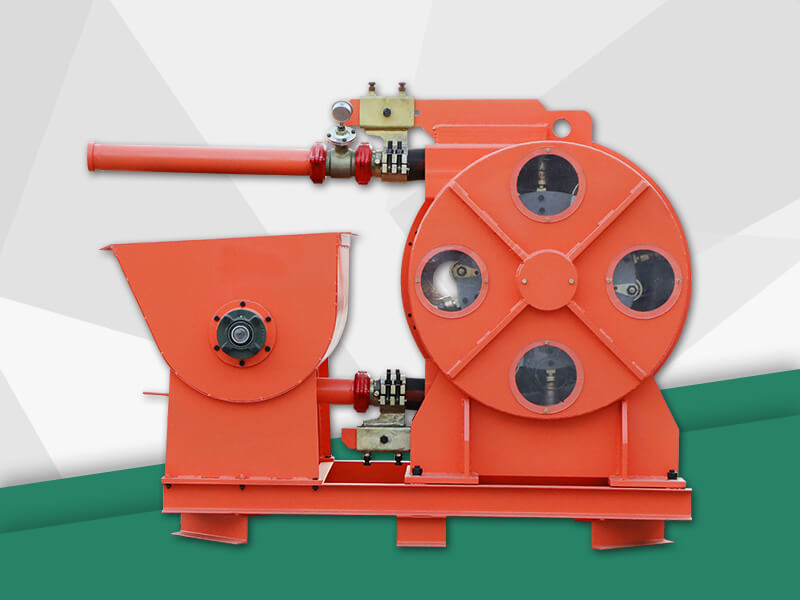

GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump, also known as hose pumps or peristaltic concrete pumps, are specialized equipment designed for transferring concrete and other viscous materials.GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump Supplier

GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump, also known as hose pumps or peristaltic concrete pumps, are specialized equipment designed for transferring concrete and other viscous materials.GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump Supplier -

1GDS1500G Hose Type Concrete Spraying Pump

1GDS1500G Hose Type Concrete Spraying Pump -

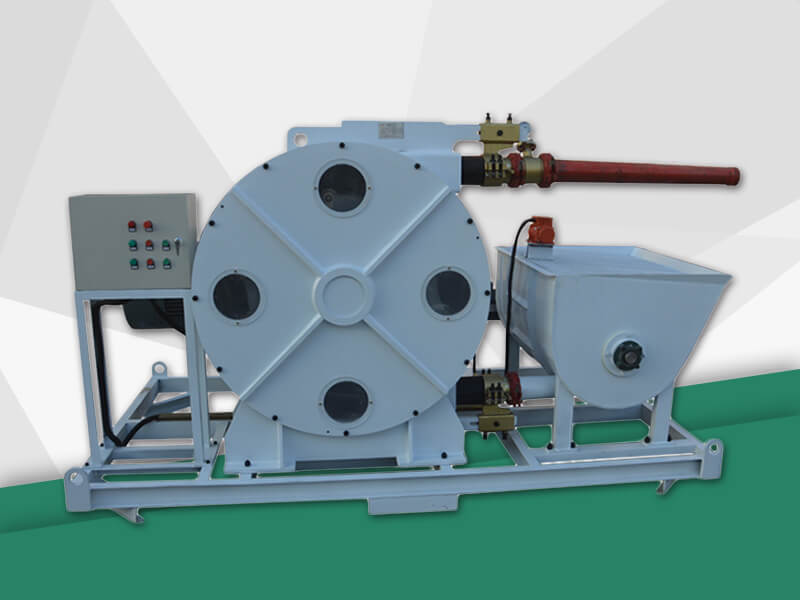

GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump is a specialized type of pump designed for use in tunnel construction, particularly for projects involving underground subway systems. This pump type is particularly suited for transporting concrete used in various tunneling applications, including lining the tunnel walls and creating structural elements.GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump

GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump is a specialized type of pump designed for use in tunnel construction, particularly for projects involving underground subway systems. This pump type is particularly suited for transporting concrete used in various tunneling applications, including lining the tunnel walls and creating structural elements.GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump -

1GCP15H-E Hose Type Concrete Pump for Pumping Concrete Slurry

1GCP15H-E Hose Type Concrete Pump for Pumping Concrete Slurry