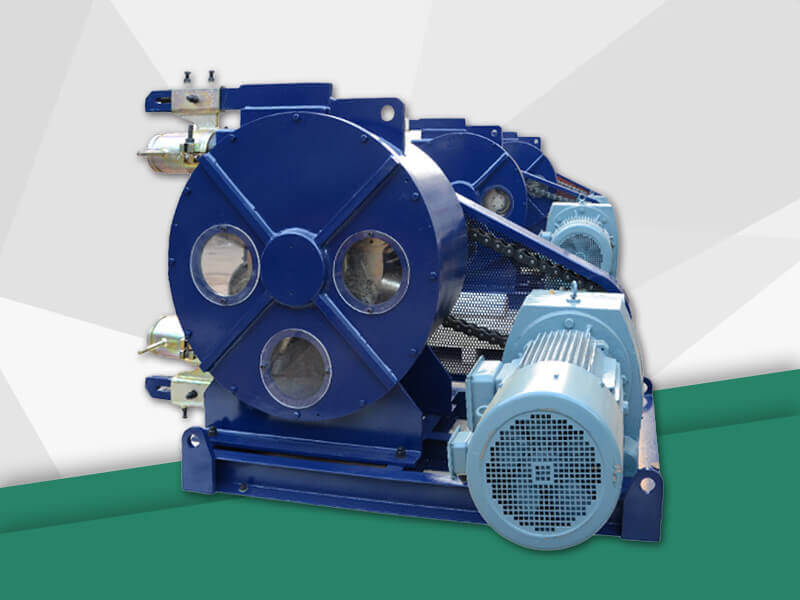

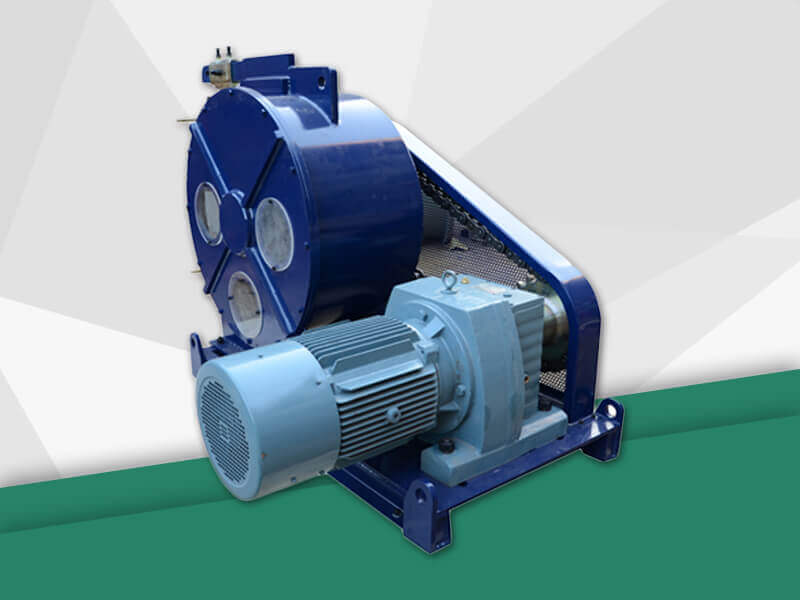

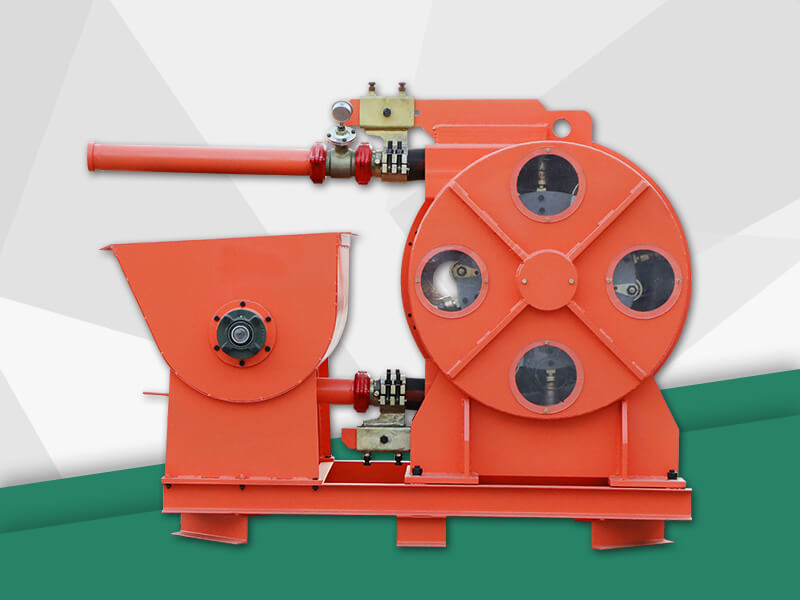

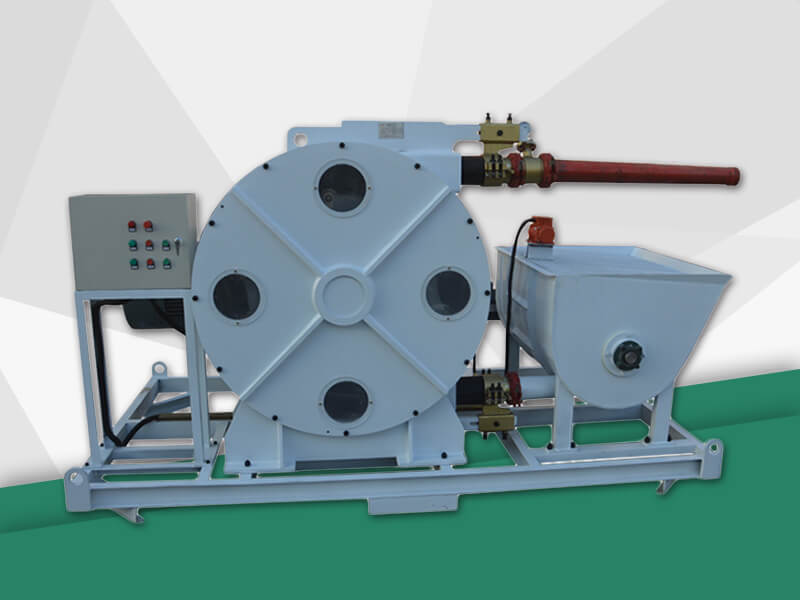

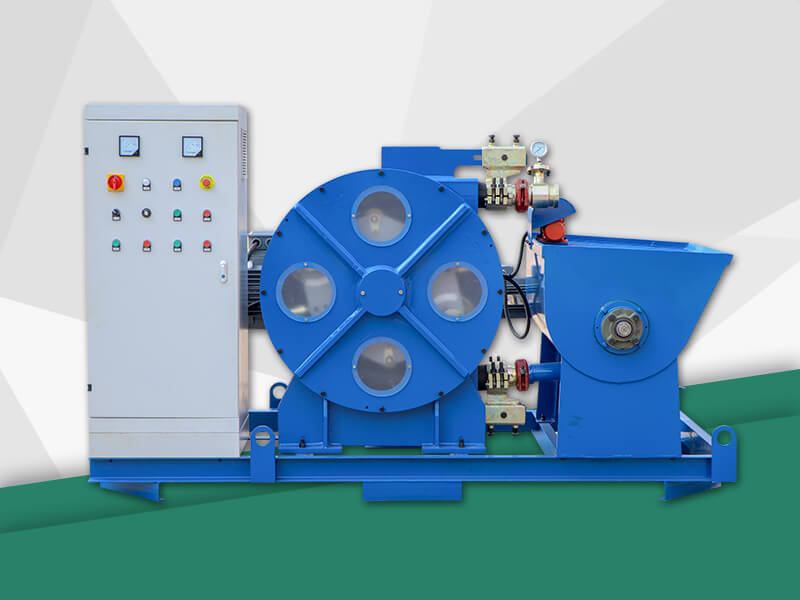

GH89-610C hose pump is used for high density abrasive slurry transport in mines industry. GH89-610C hose pump uses a wear-resistant hose suitable for pumping abrasive slurry concentrate slurry, underground passage drainage, adsorbent, mortar and mortar, etc. When conveying materials, only the hose In contact with the material, the hose is the only vulnerable item. When there is a problem, it only needs to be replaced in time to be used normally.

GH89-610C hose pumps have unique performance advantages, no seals, no valves, self-priming, dry running without damage, only hoses are replaceable parts, easy to maintain, low cost, and short downtime. When the pump is used to transport the material, the material is only in contact with the extruded hose and is easy to clean. You can change different material hoses depending on the characteristics of the material being conveyed.

GH89-610C hose pump suitable for conveying various viscosity, density, corrosive and abrasive substances, such as pumping cement slurry, mortar, lime slurry and so on. It can be used in petroleum, chemical, water treatment, mining, gold smelting, medicine, paper, ceramics and other industries.

GH89-610C hose pump products comply with national and international standards. GH89-610C hose pump has stable performance, good sealing performance, easy operation, no water cooling, beautiful and durable. They are suitable for transporting a variety of chemical media with different viscosities and temperatures and are therefore widely used in many fields.

1. Gold smelting industry: gold pulp and tailings transportation;

2. Chemical industry: acid, alkali, phosphate and titanium dioxide phosphate, titanium dioxide (met titanate) slurry, crystallization liquid, suspension, latex, resin, slime and various liquids;

3. Drilling mud in the petroleum industry: transportation of crude oil and transportation of organic solvents and fuels such as gasoline and kerosene;

4. Water treatment: sludge, lime slurry, added chemicals, sampled water, sediment transport;

5. Mining, metallurgical industry: such as gold mining in filling materials, iron oxide scale, flue mud treatment of thick slurry, underground passage drainage, adsorbents, mortar and mortar;

6. Pharmaceutical industry: transportation of liquid materials;

7. Food industry: food and beverage transportation;

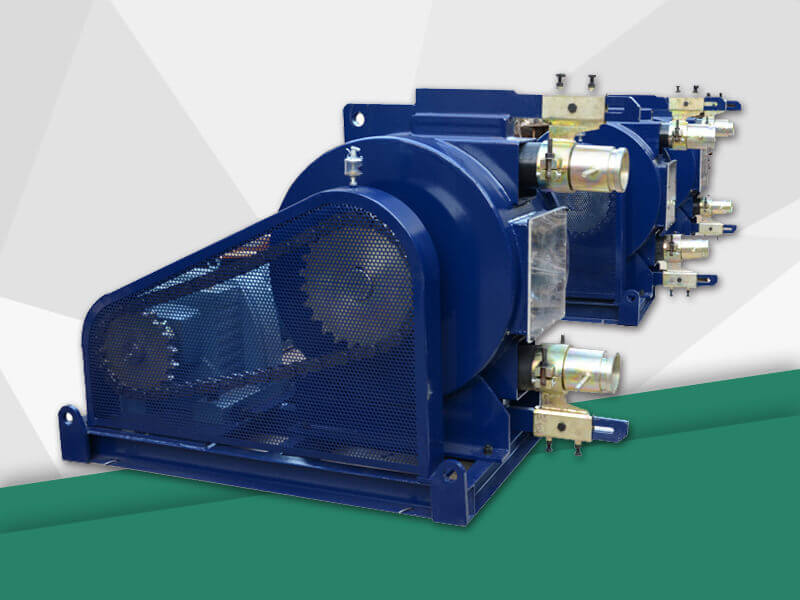

GH89-610C hose pump used for mine is suitable for pumping slurry, mortar, oil based, slurry, flammable, explosive and certain high viscosity fluids in the mining industry. GH89-610C hose pump has a strong self-reinforcing capability, high flow and easy operation.

In addition to this, GH89-610C hose pump used for mines have many features superior to other types of pumps:

-

Reversibility

-

No seals, no valves

-

Abrasion resistance

-

Corrosion-resistant

-

Self priming with high suction

-

With 1% repeat precision

-

Easy to clean

-

Dry-running without damage

-

Peristaltic tube is the only consumption part

|

Type |

GH89-610C |

|

Max. ouput |

240L/min |

|

Rotation |

45RPM |

|

Squeeze hose ID |

89mm |

|

Max. pressure |

1.0Mpa |

|

Voltage |

3 phase, 380V, 50HZ |

|

Power |

22KW |

-

GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump, also known as hose pumps or peristaltic concrete pumps, are specialized equipment designed for transferring concrete and other viscous materials.GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump Supplier

GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump, also known as hose pumps or peristaltic concrete pumps, are specialized equipment designed for transferring concrete and other viscous materials.GCP20H-H Hydraulic Motor Drive Hose Type Concrete Pump Supplier -

1GDS1500G Hose Type Concrete Spraying Pump

1GDS1500G Hose Type Concrete Spraying Pump -

GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump is a specialized type of pump designed for use in tunnel construction, particularly for projects involving underground subway systems. This pump type is particularly suited for transporting concrete used in various tunneling applications, including lining the tunnel walls and creating structural elements.GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump

GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump is a specialized type of pump designed for use in tunnel construction, particularly for projects involving underground subway systems. This pump type is particularly suited for transporting concrete used in various tunneling applications, including lining the tunnel walls and creating structural elements.GCP40H-E TBM Subway Construction Hose Squeeze Concrete Pump -

1GCP15H-E Hose Type Concrete Pump for Pumping Concrete Slurry

1GCP15H-E Hose Type Concrete Pump for Pumping Concrete Slurry