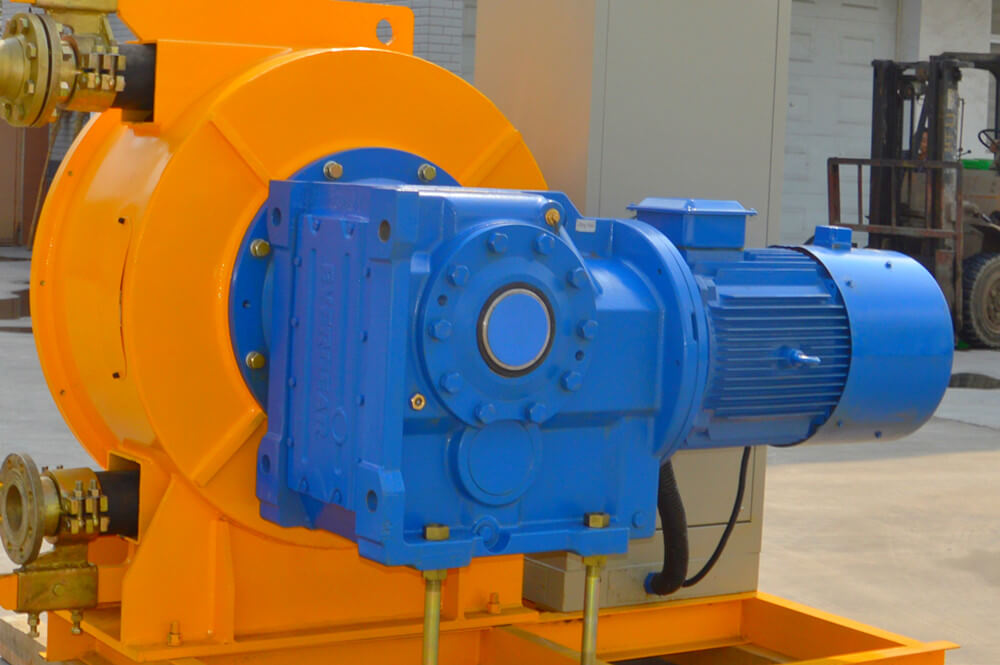

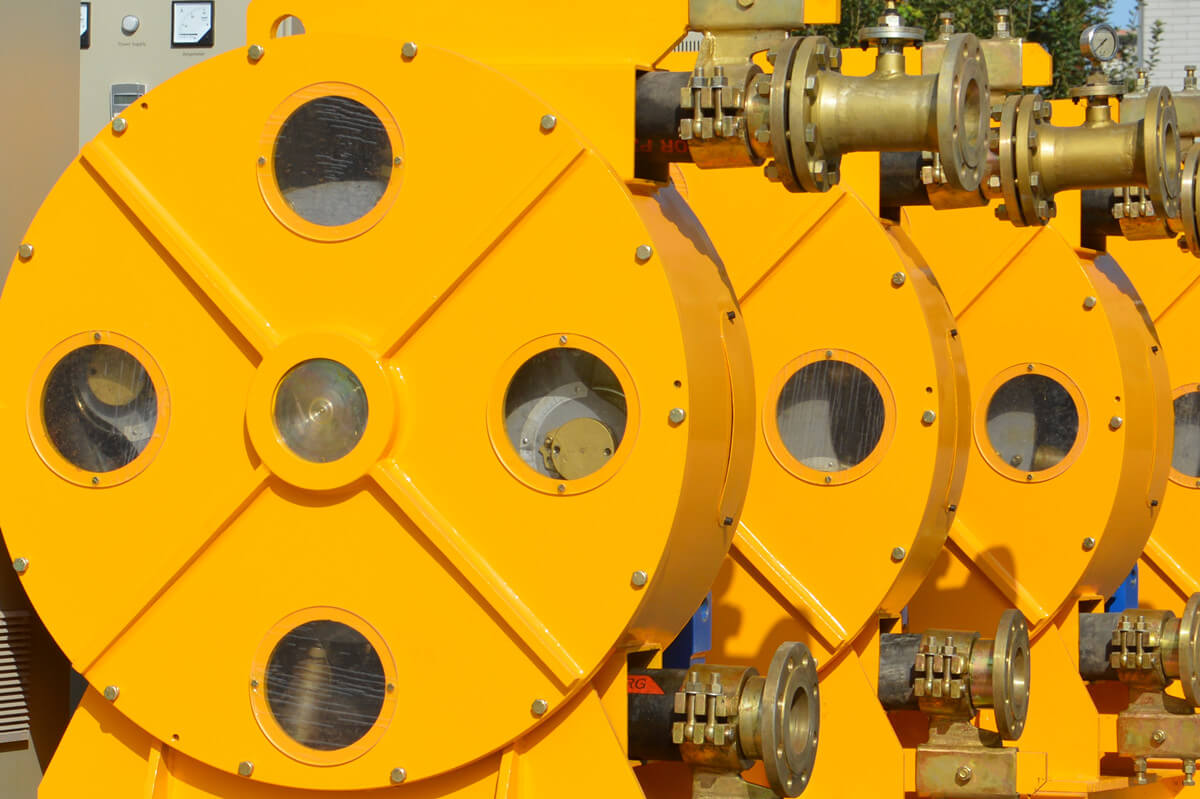

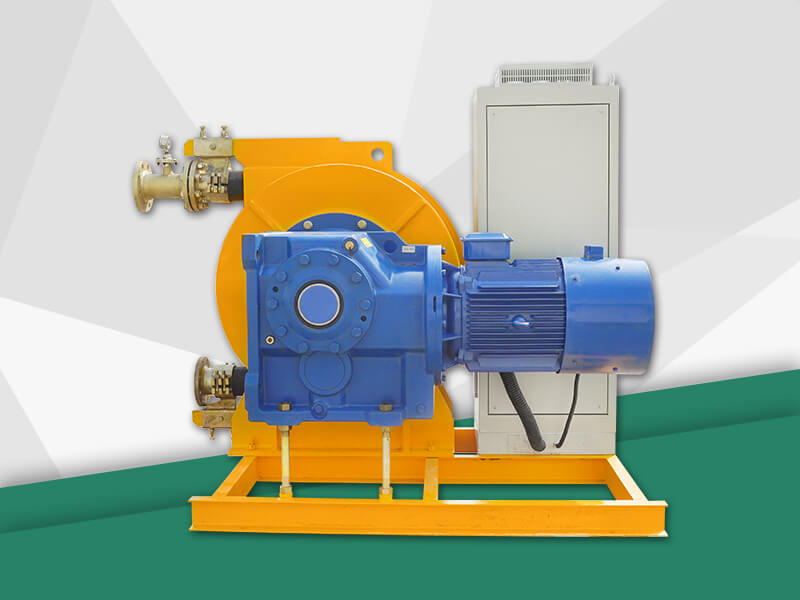

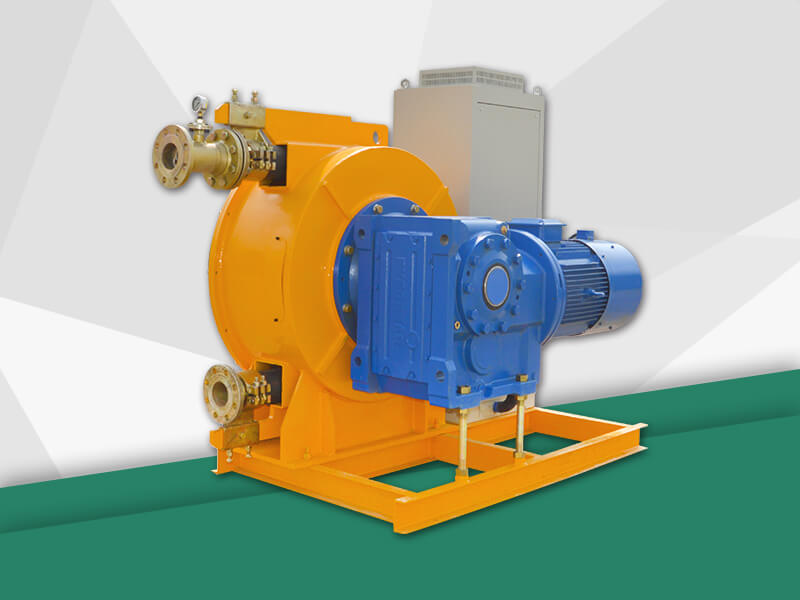

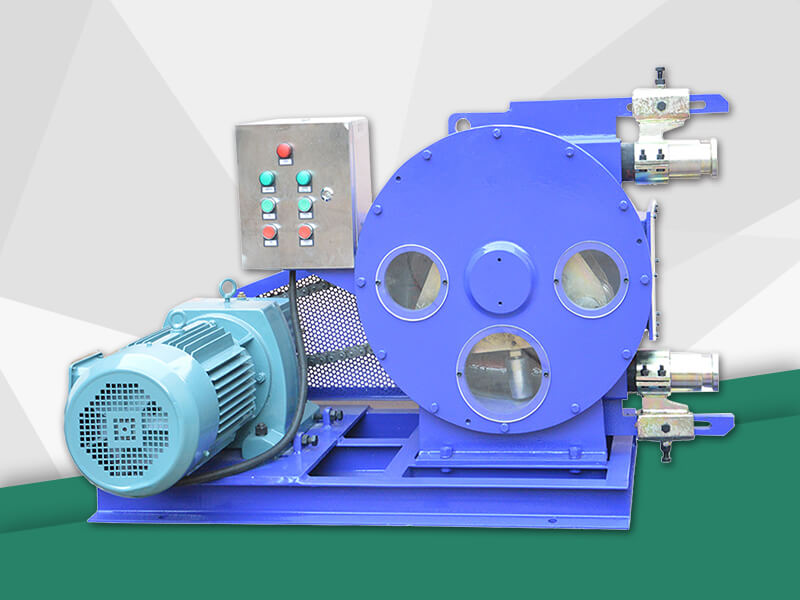

GH100-915HR superior quality customized OEM peristaltic pump is a peristaltic pump that uses the world's top ultra-high pressure hose to pump viscous liquids such as bentonite, foam concrete, mud, mortar and other pressures up to 26 bar. The operation mode of the conventional pump impeller and shaft seal has great advantages for medium transportation with large viscosity, high corrosivity and large fluid impurities.

GH100-915HR superior quality customized OEM peristaltic pump has obvious advantages in conveying strong grinding media. It means that the hose pump has a valveless and sealed structure without any leakage and pollution. Only the inner cavity of the rubber hose is in contact with the medium, and other components are completely independent of outside the medium; the flow can be adjusted linearly, without any blockage of fluid transport with high viscosity and impurities.

GH100-915HR superior quality customized OEM peristaltic pumps have many advantages: they have good self-priming ability, almost perfect vacuum to absorb liquid; transport contains foam, bubbles without air resistance; conveying high viscosity, shear sensitive medium is also strong; The fixed displacement is independent of the outlet pressure and is a natural metering pump.

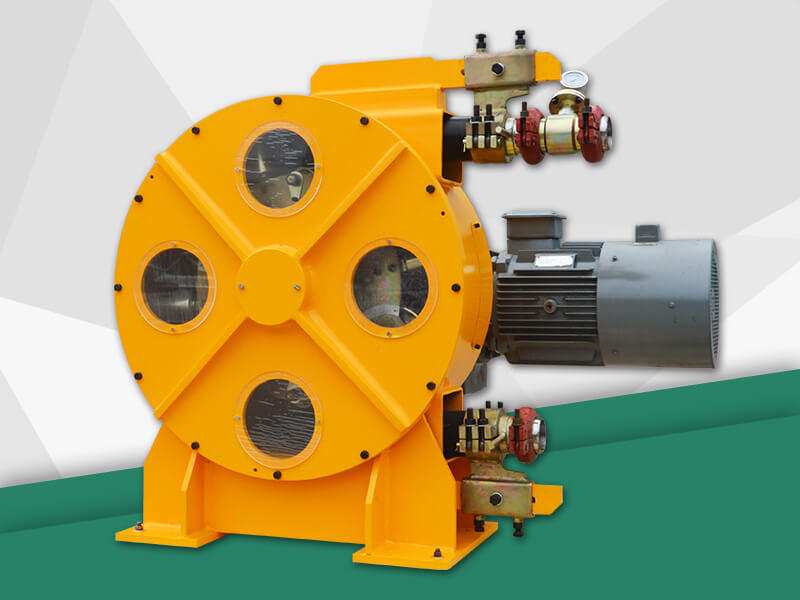

Working principle of peristaltic hose pump:

Peristaltic pump, also known as constant flow pump and hose pump, is a device that pumps fluid by alternately squeezing and releasing elastic hose. Its working principle is similar to that of pinching a hose with two fingers. As the fingers move, negative pressure is formed in the tube, and the liquid flows. In a peristaltic pump, the motor drives the roller to rotate. As the roller revolves around the motor shaft, it also rotates while squeezing the pump tube to reduce the friction between the roller surface and the pump tube surface. When the roller continues to roll forward, because the pump tube is elastic, the area of the pump tube that is no longer squeezed will recover its deformation, so that in the process of returning to the shape of a circular tube, negative pressure is formed near the area, sucking in the upstream liquid or gas. When the next roller arrives, the liquid sucked in by the area is squeezed back again, and the cycle is repeated to achieve continuous liquid or gas delivery.

GH100-915HR superior quality customized OEM peristaltic pump is a kind of peristaltic pump. It adopts the international top-grade ultra-high pressure hose, which can pump bentonite, foam concrete, mud, mortar and other viscous liquids up to 26 bar.

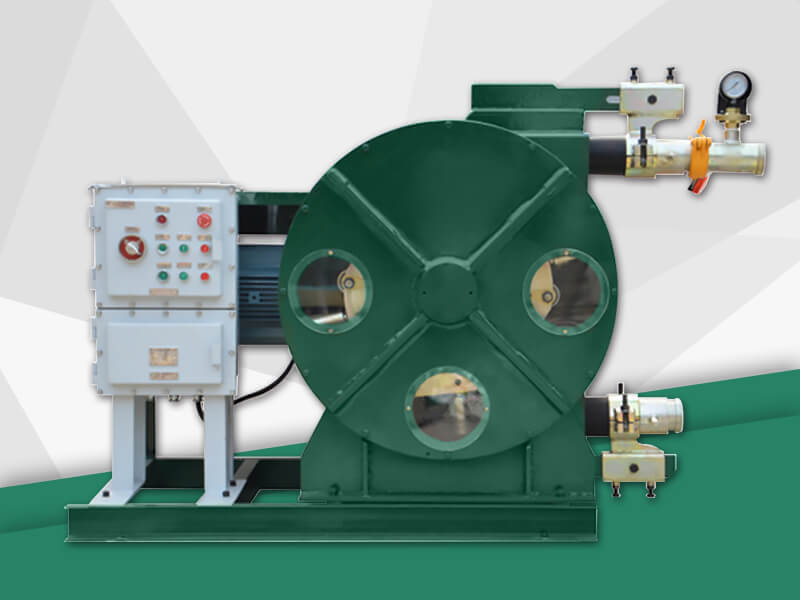

The electric control box of the GH100-915HR superior quality customized OEM peristaltic pump is optional, and the low-pressure can be reduced according to different conditions of the customer.

GH100-915HR superior quality customized OEM peristaltic pumps are used in many industries:

1. Gold smelting industry: gold pulp and tailings transportation;

2. Chemical industry: acid, alkali, phosphate and titanium dioxide phosphate, titanium dioxide (met titanate) slurry, crystallization liquid, suspension, latex, resin, slime and various liquids;

3. Drilling mud in the petroleum industry: transportation of crude oil and transportation of organic solvents and fuels such as gasoline and kerosene;

4. Water treatment: sludge, lime slurry, added chemicals, sampled water, sediment transport;

5. Mining, metallurgical industry: such as gold mining in filling materials, iron oxide scale, flue mud treatment of thick slurry, underground passage drainage, adsorbents, mortar and mortar;

Self-priming.

Only tube to replace.

Dry-running without damage.

Reversible.

High pressure, high flow.

No Seals, no valves.

No contact between product and the mechanical parts.

Able to pump products with solid parts inside.

Easy maintenance, low-cost, short down time.

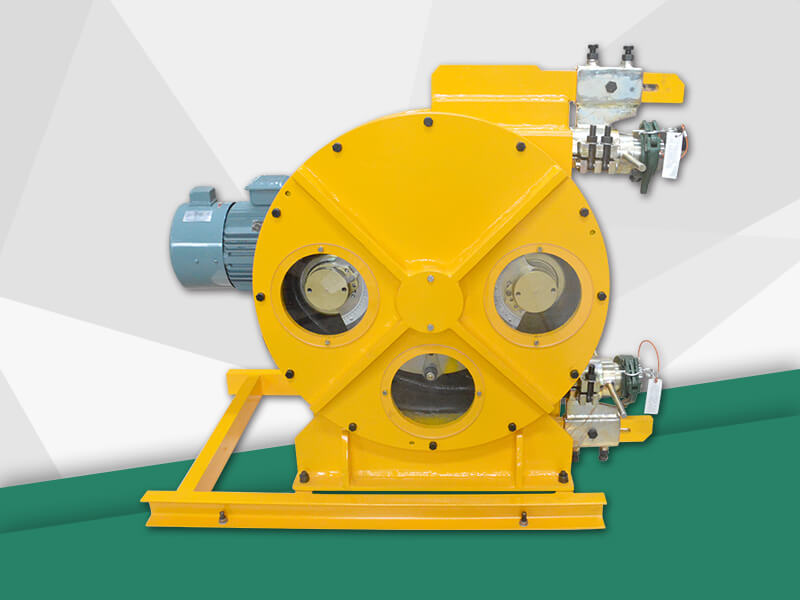

Advantages of GH100-915HR customized OEM peristaltic pump:

No pollution: The fluid only contacts the pump tube, not the pump body, thus avoiding the risk of cross contamination.

Constant flow and high precision: The peristaltic pump can provide a stable flow rate, and the flow rate is easy to adjust, with high repeatability and strong stability.

Low shear force: The liquid is squeezed out of the pump tube by peristalsis, and no shear force is generated, which is suitable for conveying shear-sensitive or highly corrosive fluids.

Strong corrosion resistance: It can convey various fluids, including organic solvents and corrosive liquids.

Simple maintenance: There are no valves and seals, and the tube is the only part in contact with the medium, which is easy to replace.

Two-way equal flow delivery capacity: The peristaltic pump can run dry for a long time, without water delivery, and can also deliver air, with gas-liquid-solid three-phase mixed delivery capacity.

|

Type |

GH100-915HR Customized Peristaltic Pump |

|

Output |

30m3/h |

|

Rotation |

32RPM |

|

Squeeze hose ID |

100mm |

|

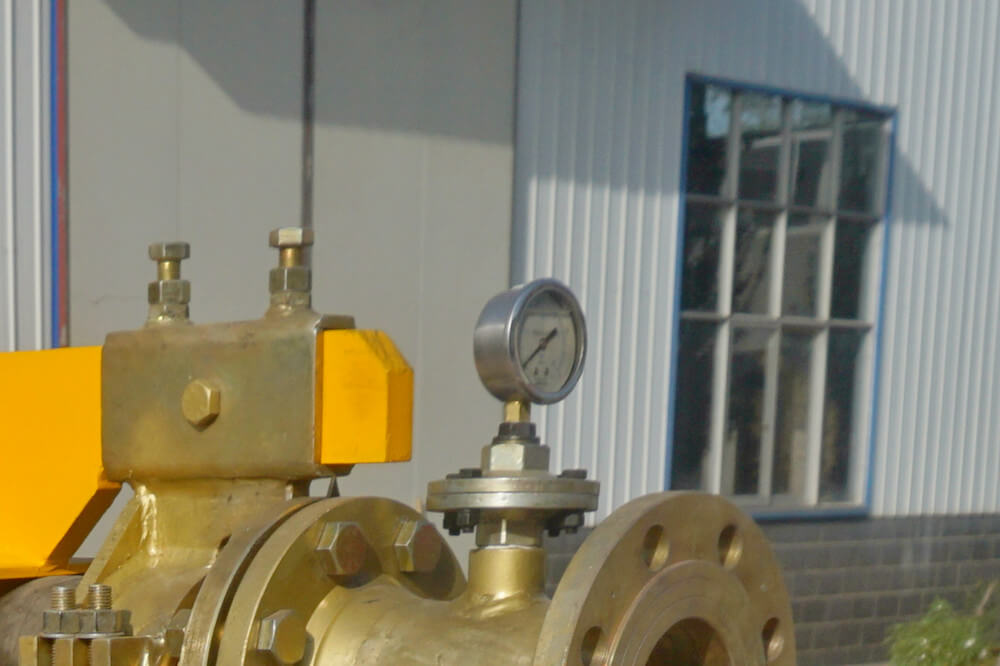

Working pressure |

26bar |

|

Max. Aggregate Size |

20mm |

|

Max. Suction Lift |

5m |

|

Motor Power |

45KW |

|

Weight |

1750kg |

-

Bentonite suspensions usually have high viscosity, and traditional pumps may face clogging or severe wear problems when transporting. Industrial Peristaltic Pumps pump fluids by squeezing hoses and do not rely on rotating parts such as impellers or gears, so they can easily handle high-viscosity media.GH76-915HR Industrial Peristaltic Pump for Pumping Bentonite

Bentonite suspensions usually have high viscosity, and traditional pumps may face clogging or severe wear problems when transporting. Industrial Peristaltic Pumps pump fluids by squeezing hoses and do not rely on rotating parts such as impellers or gears, so they can easily handle high-viscosity media.GH76-915HR Industrial Peristaltic Pump for Pumping Bentonite -

1GH65-680HR Hose Pump for Pumping Concrete

1GH65-680HR Hose Pump for Pumping Concrete -

High-pressure peristaltic pumps used in mining applications are designed to handle abrasive, viscous, and corrosive fluids with high efficiency and minimal maintenance. High-pressure peristaltic pumps for mining need to be constructed with materials that withstand harsh environments, such as reinforced housings and chemically resistant tubing (e.g., rubber, EPDM, or Viton).GH76-770HR High Pressure Peristaltic Pump Used for Mine

High-pressure peristaltic pumps used in mining applications are designed to handle abrasive, viscous, and corrosive fluids with high efficiency and minimal maintenance. High-pressure peristaltic pumps for mining need to be constructed with materials that withstand harsh environments, such as reinforced housings and chemically resistant tubing (e.g., rubber, EPDM, or Viton).GH76-770HR High Pressure Peristaltic Pump Used for Mine -

GH50-445HR Industrial Hose Pump (a type of peristaltic pump) are an excellent solution for transferring mining waste, as they are designed to handle viscous, abrasive, and corrosive materials commonly found in mining waste streams.GH50-445HR Industrial Hose Pump for Transfer Mining Waste

GH50-445HR Industrial Hose Pump (a type of peristaltic pump) are an excellent solution for transferring mining waste, as they are designed to handle viscous, abrasive, and corrosive materials commonly found in mining waste streams.GH50-445HR Industrial Hose Pump for Transfer Mining Waste