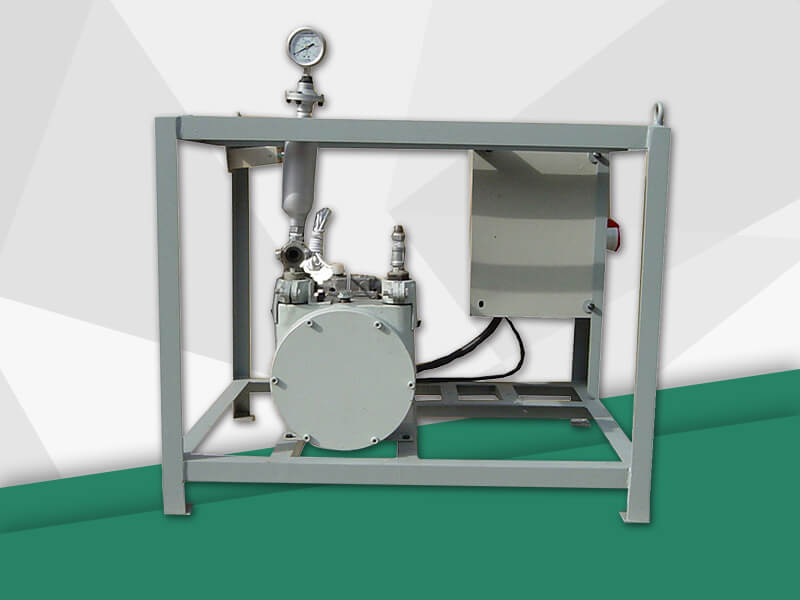

GH25R metering peristaltic pump for medicament addition, drinking water disinfection, pH adjustment in drinking water and industrial wastewater treatment, industrial cooling water preparation, flocculant, mineralizer addition, disinfection laboratory, etc.

GH25R metering peristaltic pump for pharmaceutical industrys have many advantages: they have the good self-priming ability, almost perfect vacuum to absorb liquid; transport contains foam, bubbles without air resistance; conveying high viscosity, shear sensitive medium is also strong; The fixed displacement is independent of the outlet pressure and is a natural metering pump.

GH25R metering peristaltic pump for pharmaceutical industry is a new multi-purpose industrial peristaltic hose pump developed by advanced technology. The pump has no seal, no leakage, strong self-priming ability, simple structure, and convenient operation and maintenance. Suitable for conveying various viscosity, density, corrosive and abrasive substances. It can be used in petroleum, chemical, water treatment, mining, gold smelting, medicine, paper, ceramics, and other industries.

GH25R metering peristaltic pumps are used for the metering of additives in the pharmaceutical industry. The chemical industry is used to add chemical media containing acidic and corrosive substances; metering pumps for environmentally friendly industrial water treatment. Adjustable flow, self-priming ability, high metering accuracy and repeatability can reach ±1%.

GH25R metering peristaltic pump can be used for drinking water disinfection, pH adjustment in drinking water and industrial wastewater treatment, industrial cooling water preparation, flocculant, beneficiation-agent addition, disinfection laboratory, etc.

GH25R metering peristaltic pump can be used for drinking water disinfection, pH adjustment in drinking water and industrial wastewater treatment, industrial cooling water preparation, flocculant, beneficiation-agent addition, disinfection laboratory, etc.

GH25R metering peristaltic pump is widely used because of its unique advantages.

1. No valves, perfect pump for high viscosity fluids, simple structure, easy to clean.

2. High measurement accuracy, repeatability ± 1%.

3. Self-priming ability, suction height.

4. Uniform continuous pumping, pulse small

5. No bear, easy to clean and maintain.

6. Less wear parts, the only hose is wear part, low cost.

7. Flow infinitely adjustable for different requirements.

8. Just replace the different type hose, can pump the different material.

|

Output |

240-1200L/h ( 4-20L/min) |

|

Max. Particle Size |

3mm |

|

Max.Work Pressure |

15 bar |

|

Max. Suck lift |

2 meter |

|

Hose Tube ID |

25mm |

|

Electric motor |

1.5Kw, 3 phase 380V |

|

Overall Dimension(length×width×height) |

0.86×0.76×0.85m |

|

Net Weight |

125kg |

-

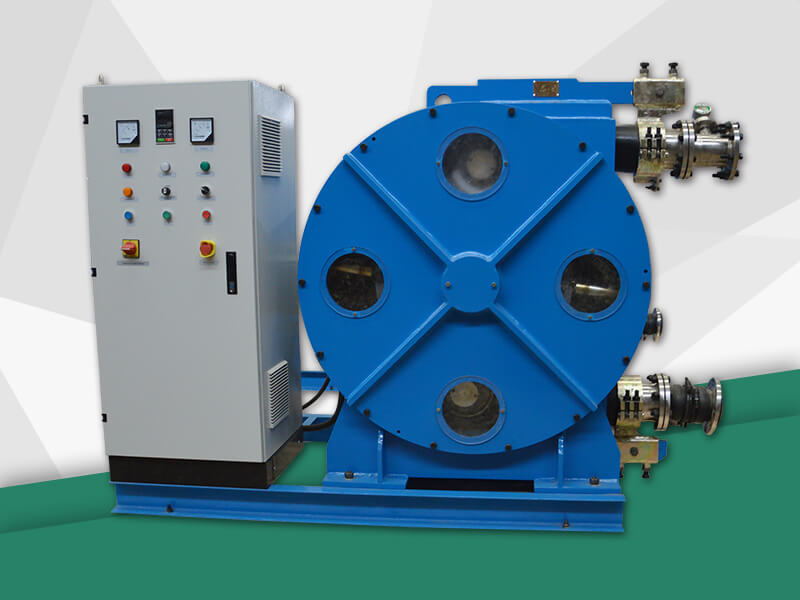

Heavy Duty Hose Pumps are specialized pumps designed for high-pressure and heavy-duty applications. They are often used in industries that require the transfer of viscous, abrasive, or corrosive fluids.GH125-915R Heavy Duty Hose Pump for Sale

Heavy Duty Hose Pumps are specialized pumps designed for high-pressure and heavy-duty applications. They are often used in industries that require the transfer of viscous, abrasive, or corrosive fluids.GH125-915R Heavy Duty Hose Pump for Sale -

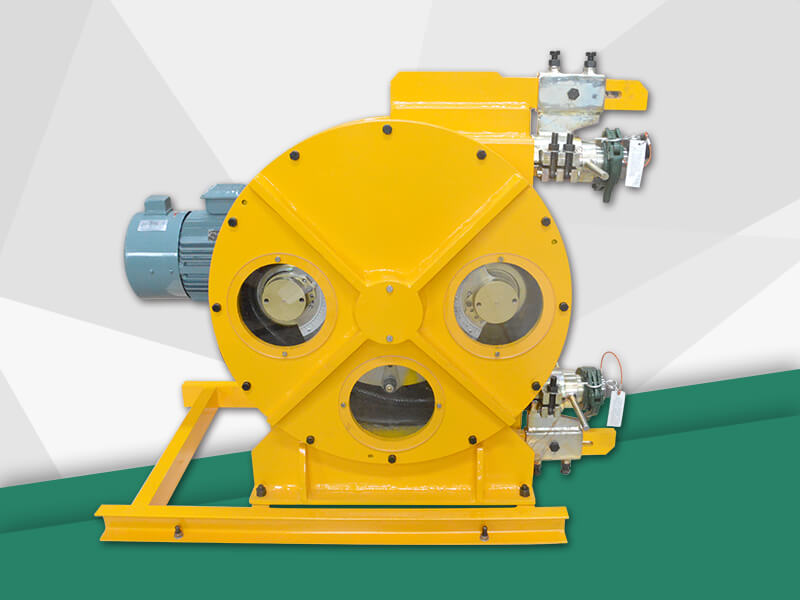

During tunnel excavation and support, precision industrial peristaltic pumps can be used for grouting and grouting operations to evenly inject slurry into the rock and soil around the tunnel, improving the stability and safety of the tunnel.GH100-915R Peristaltic Pump for Tunnel Underground

During tunnel excavation and support, precision industrial peristaltic pumps can be used for grouting and grouting operations to evenly inject slurry into the rock and soil around the tunnel, improving the stability and safety of the tunnel.GH100-915R Peristaltic Pump for Tunnel Underground -

Peristaltic hose pumps can pump fluids with high efficiency and are suitable for situations in TBM where continuous and stable pumping of various materials (such as foamed concrete, lightweight concrete, mortar, cement slurry and refractory materials, etc.) is required.GH76-915R Industrial Peristaltic Hose Pump for TBM

Peristaltic hose pumps can pump fluids with high efficiency and are suitable for situations in TBM where continuous and stable pumping of various materials (such as foamed concrete, lightweight concrete, mortar, cement slurry and refractory materials, etc.) is required.GH76-915R Industrial Peristaltic Hose Pump for TBM -

GH65-680R Metering Peristaltic Pump for Pharmaceutical Addition

GH65-680R Metering Peristaltic Pump for Pharmaceutical Addition