GH76-770R chemical peristaltic pumps are used in a wide range of applications in the chemical industry, such as pumping paints, coatings and pigments for paint plants; transporting or discharging fiber liquids, dyes or waste water for textile mills; pumping or metering of corrosive and hazardous materials in pharmaceutical plants.

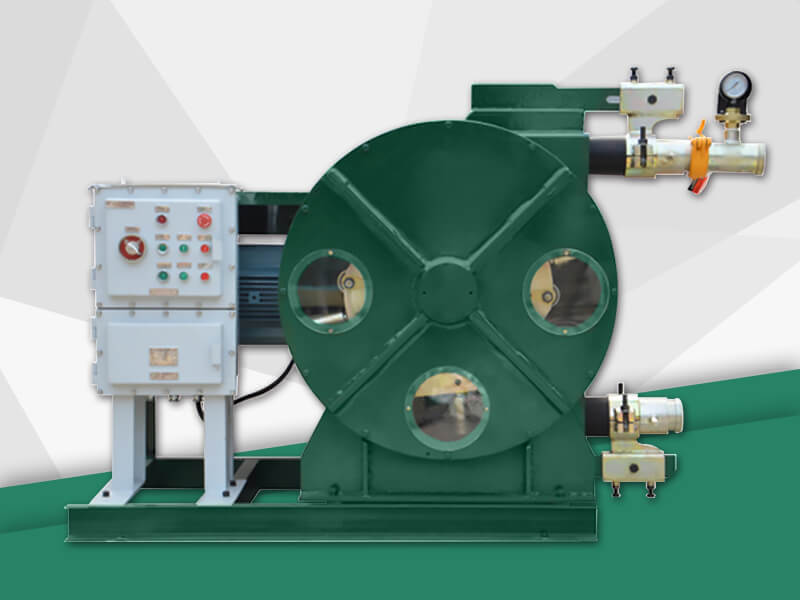

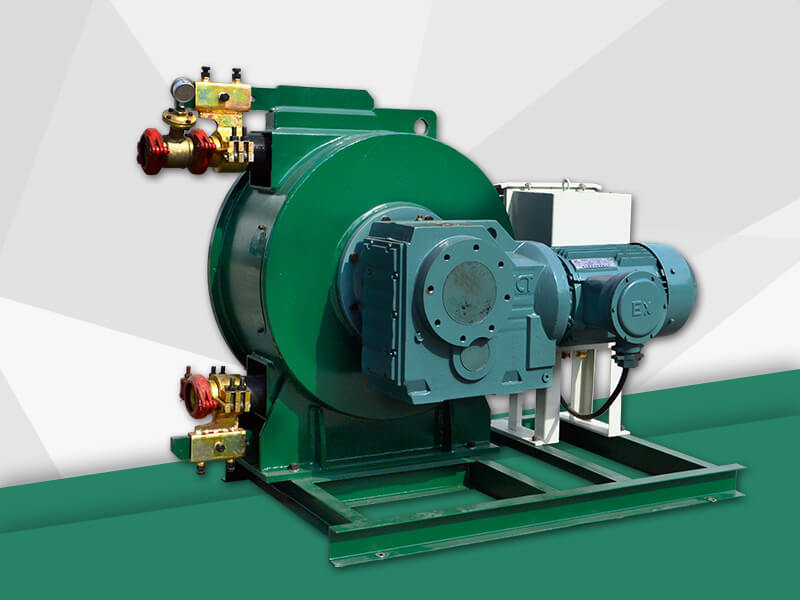

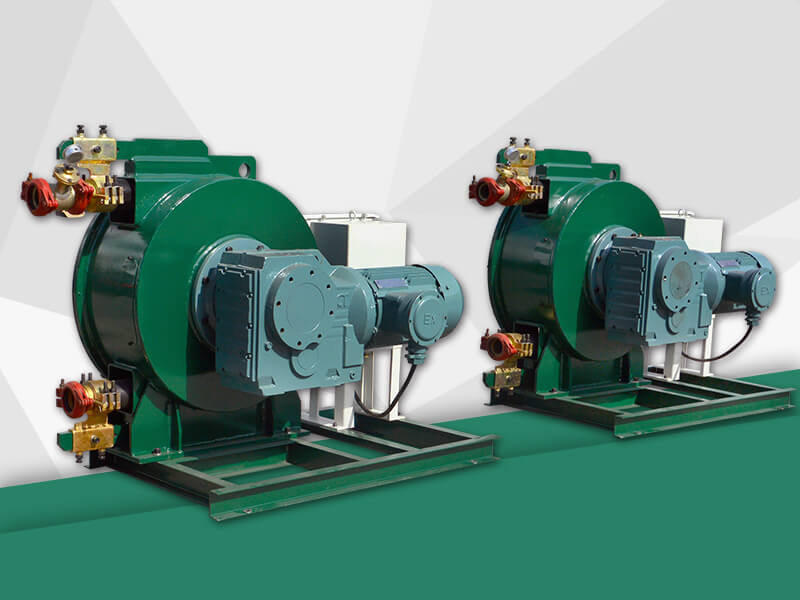

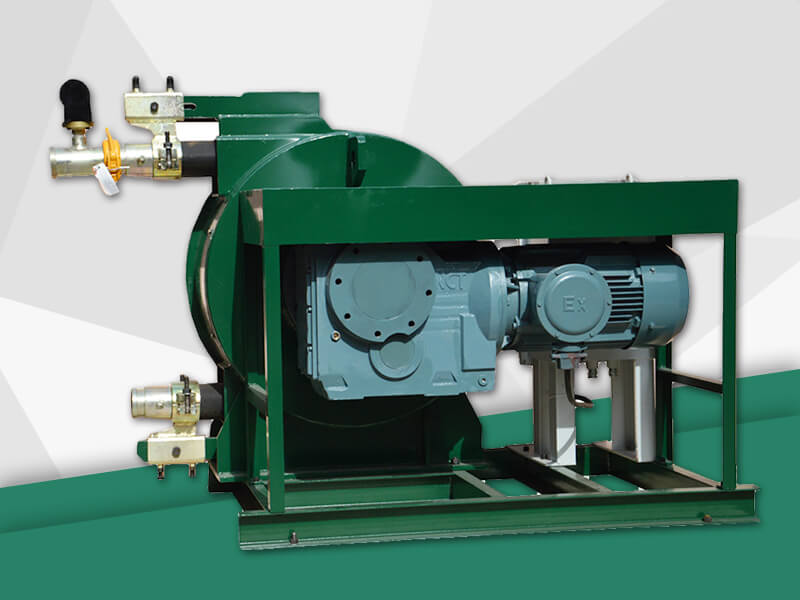

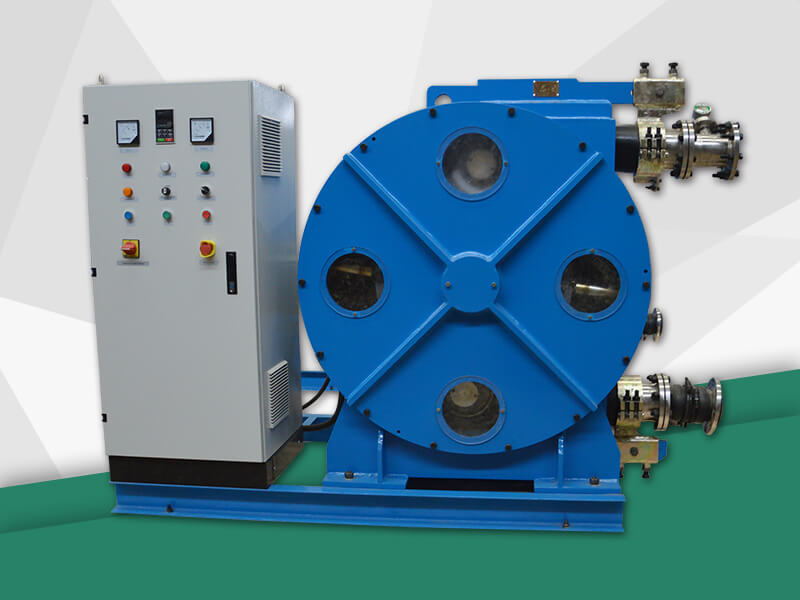

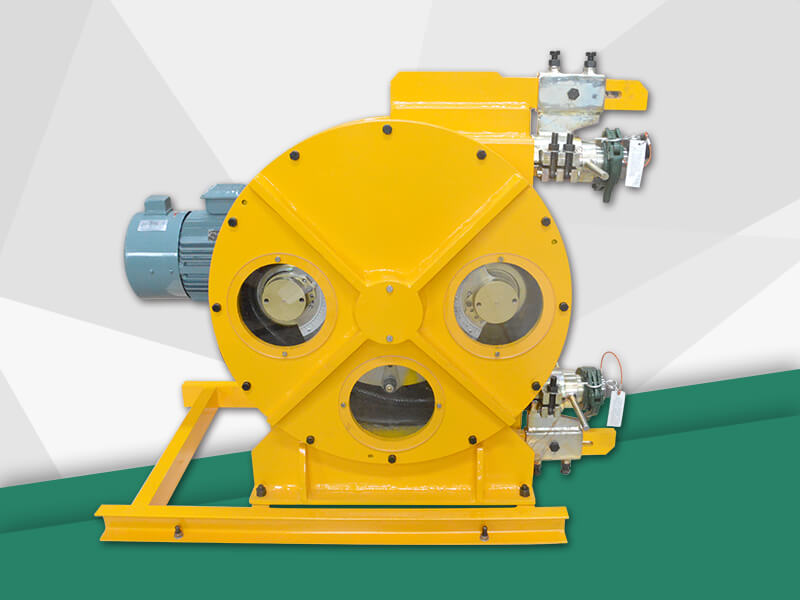

GH76-770R chemical peristaltic pumps are usually composed mainly of pump hoses, rotors, rollers, idlers, squeeze hoses and drive units. The squeeze hose is U-shaped in the pump room, and the hose is deformed when the rotor drives the drum to rotate. After the drum rotates, the deformed hose will recover through its elasticity. Therefore, the negative pressure generated by the hose attracts the slurry and is discharged through the outlet under the push of the roller, eventually forming a pressure transfer of the slurry.

GH76-770R chemical peristaltic pump has added explosion-proof motors, control equipment, and frequency converters. In the chemical industry, it can be used to pump pumping oil base,oil slurries, corrosive, flammable, explosive and some high viscosity fluids.Compared to other types of pumps, GH76-770R chemical peristaltic pumps are easy to operate and maintain, and only the hose is in contact with the material. In case of problems, just replace the squeeze hose in time.

GH76-770R chemical peristaltic pumps are used in a wide range of applications in the chemical industry, such as pumping paints, coatings and pigments for paint plants; transporting or discharging fiber liquids, dyes or waste water for textile mills; pumping or metering of corrosive and hazardous materials in pharmaceutical plants .

In addition to its wide application in the chemical industry, GH76-770R chemical peristaltic pumps are also widely used in many other industries.

1. Gold smelting industry: gold pulp and tailings transportation;

2. Chemical industry: acid, alkali, phosphate and titanium dioxide phosphate, titanium dioxide (met titanate) slurry, crystallization liquid, suspension, latex, resin, slime and various liquids;

3. Drilling mud in the petroleum industry: transportation of crude oil and transportation of organic solvents and fuels such as gasoline and kerosene;

4. Water treatment: sludge, lime slurry, added chemicals, sampled water, sediment transport;

5. Mining, metallurgical industry: such as gold mining in filling materials, iron oxide scale, flue mud treatment of thick slurry, underground passage drainage, adsorbents, mortar and mortar;

6. Pharmaceutical industry: transportation of liquid materials;

7. Food industry: food and beverage transportation;

GH76-770R chemical peristaltic pump used for chemical industry is suitable for pumping slurry, mortar, oil based, slurry, flammable, explosive and certain high viscosity fluids in the mining industry. GH76-770R chemical peristaltic pump has a strong self-reinforcing capability, high flow and easy operation.

In addition to this, GH76-770R chemical peristaltic pump used for mines have many features superior to other types of pumps:

-

Reversibility

-

No seals, no valves

-

Abrasion resistance

-

Corrosion-resistant

-

Self priming with high suction

-

With 1% repeat precision

-

Easy to clean

-

Dry-running without damage

-

Peristaltic tube is the only consumption part

|

Type |

GH76-770R |

|

Max. output |

300L/min or 18m3/h ( at 0.5Mpa, 50HZ) |

|

Rotation |

35RPM |

|

Squeeze hose ID |

76mm |

|

Max. pressure |

1.5 Mpa |

|

Voltage |

3 phase, 380V, 50HZ |

|

Power |

15KW |

-

Heavy Duty Hose Pumps are specialized pumps designed for high-pressure and heavy-duty applications. They are often used in industries that require the transfer of viscous, abrasive, or corrosive fluids.GH125-915R Heavy Duty Hose Pump for Sale

Heavy Duty Hose Pumps are specialized pumps designed for high-pressure and heavy-duty applications. They are often used in industries that require the transfer of viscous, abrasive, or corrosive fluids.GH125-915R Heavy Duty Hose Pump for Sale -

During tunnel excavation and support, precision industrial peristaltic pumps can be used for grouting and grouting operations to evenly inject slurry into the rock and soil around the tunnel, improving the stability and safety of the tunnel.GH100-915R Peristaltic Pump for Tunnel Underground

During tunnel excavation and support, precision industrial peristaltic pumps can be used for grouting and grouting operations to evenly inject slurry into the rock and soil around the tunnel, improving the stability and safety of the tunnel.GH100-915R Peristaltic Pump for Tunnel Underground -

Peristaltic hose pumps can pump fluids with high efficiency and are suitable for situations in TBM where continuous and stable pumping of various materials (such as foamed concrete, lightweight concrete, mortar, cement slurry and refractory materials, etc.) is required.GH76-915R Industrial Peristaltic Hose Pump for TBM

Peristaltic hose pumps can pump fluids with high efficiency and are suitable for situations in TBM where continuous and stable pumping of various materials (such as foamed concrete, lightweight concrete, mortar, cement slurry and refractory materials, etc.) is required.GH76-915R Industrial Peristaltic Hose Pump for TBM -

GH65-680R Metering Peristaltic Pump for Pharmaceutical Addition

GH65-680R Metering Peristaltic Pump for Pharmaceutical Addition