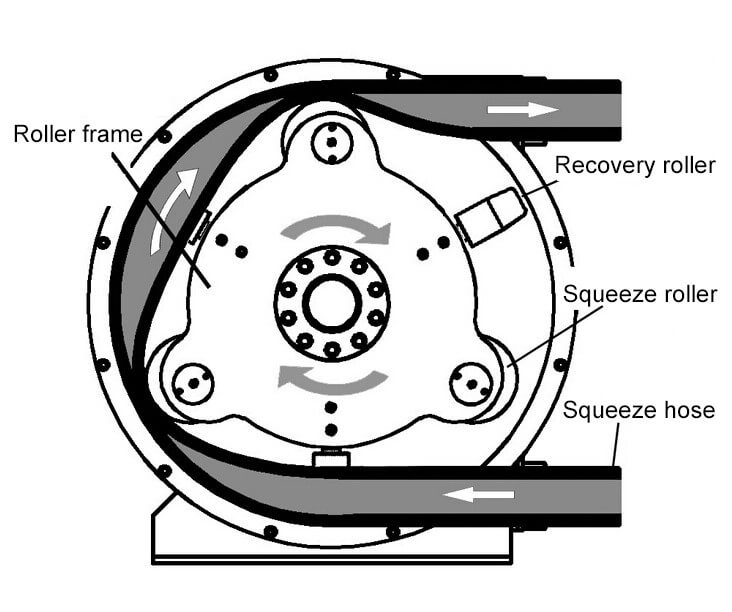

Industrial hose pumps pump fluid by squeezing and releasing the elastic delivery hose of the pump. Just like squeezing the hose with two fingers, when the finger moves, negative pressure builds up in the tube and the fluid flows. A peristaltic pump is a "pillow" fluid formed by a section of pump between two rollers.

The volume of the pillow core depends on the inner diameter of the pump tube and the geometric characteristics of the rotor. The flow rate depends on the product of the speed of the pump head and the size of the "sleeper", and the number of "sleepers" produced per revolution of the rotor.

The size of the pillow is usually constant (unless the fluid is particularly viscous). Compared with pumps with the same rotor diameter, a larger "pillow" volume is produced, and the volume of fluid transferred per turn of the rotor is larger, but the pulsation is also larger. This is similar to the case of membrane valves. A pump with a smaller "pillow" volume is produced, and the volume of fluid transferred per turn of the rotor is smaller; moreover, a small "pillow" formed quickly and continuously makes the fluid flow more stable. This is similar to the case of gear pumps.

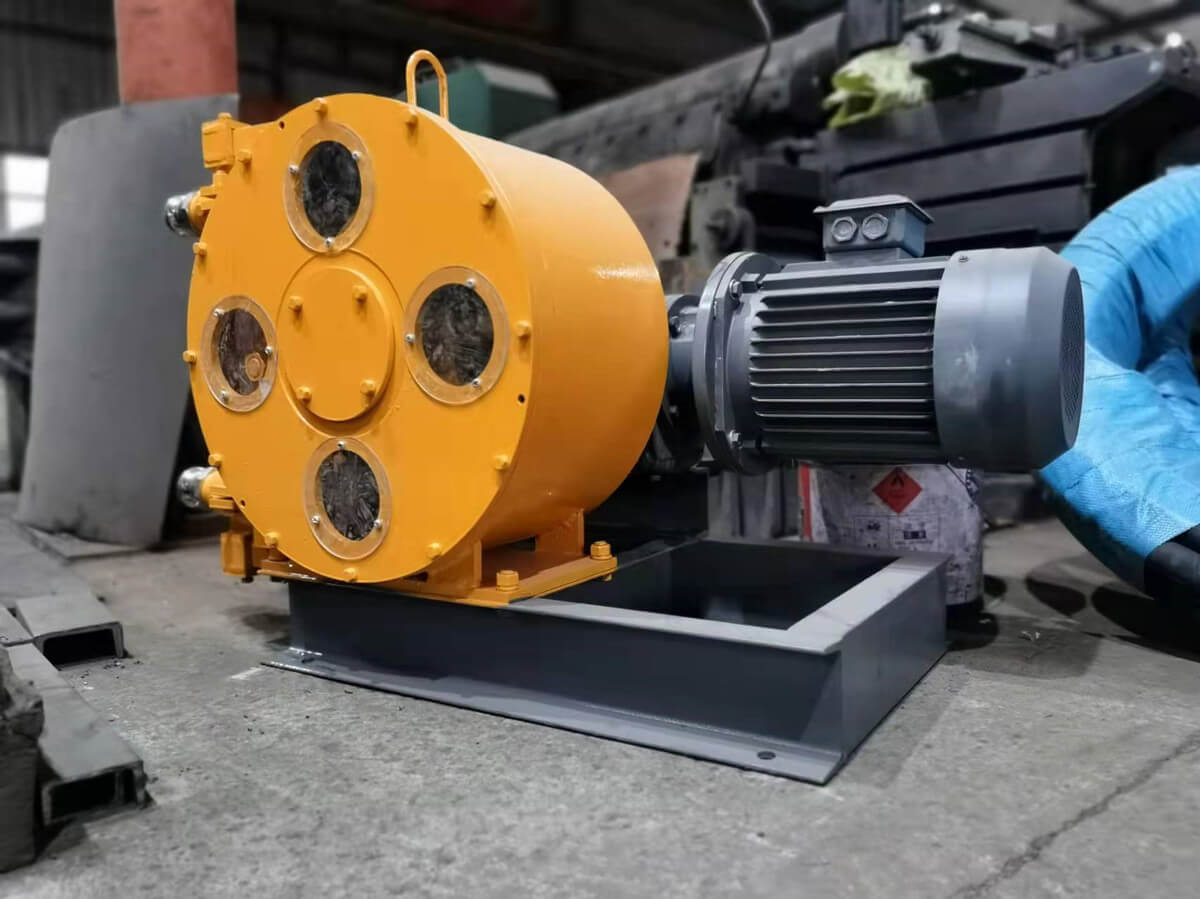

Industrial hose pumps have bidirectional equal flow delivery capacity; in the absence of liquid idling, they will not damage any parts of the pump; up to 98% of vacuum can be generated; there are no valves, mechanical seals and packing seals, and there is no such Leakage and maintenance factors; can easily transport solid, liquid or gas-liquid mixed-phase fluids to allow the diameter of the solids contained in the fluid to reach 40% of the inner diameter of the tubular member; can transport various grinding, corrosion, oxygen sensitive materials and various Kinds of food; the operation of replacing parts only with hose replacement is very simple, except for the hose, the conveyed product does not touch any parts.