Milk of lime is a suspension of small solid particles of calcium hydroxide dispersed in water. Many processes involve adding and transporting milk of lime. For example, in sewage treatment, many treatment methods are used, such as chemical methods, ion exchange methods, and activated carbon adsorption methods, of which the "precipitation method" is the most well-known. The so-called precipitation method uses lime as a sediment to reduce the turbidity and hardness of sewage. Lime milk is favored by many company departments because of its low cost and relatively high processing efficiency. So what process is used to solve the transportation of lime milk?

In traditional process solutions, everyone uses a rotary pump. Due to the movement and rotation of the rotor, the rotor pump will generate suction (ie vacuum) at the inlet during the rotation, thereby sucking in the medium and realizing the transfer process. And it can reach quantitative standards during transportation. For long-term use, the rotor pump has a relatively stable effect. However, it has been found that this operation causes the rotor of the rotary pump to be very worn, requires frequent replacement, and increases transportation costs. Tests and experiments show that the lime milk medium has certain abrasiveness. During operation, friction will occur in the rotor, and when the rotor rotates, its life is greatly shortened, and the maintenance cost is greatly increased, friction will occur again. Customers are most worried about prolonged process downtime, which will affect production problems.

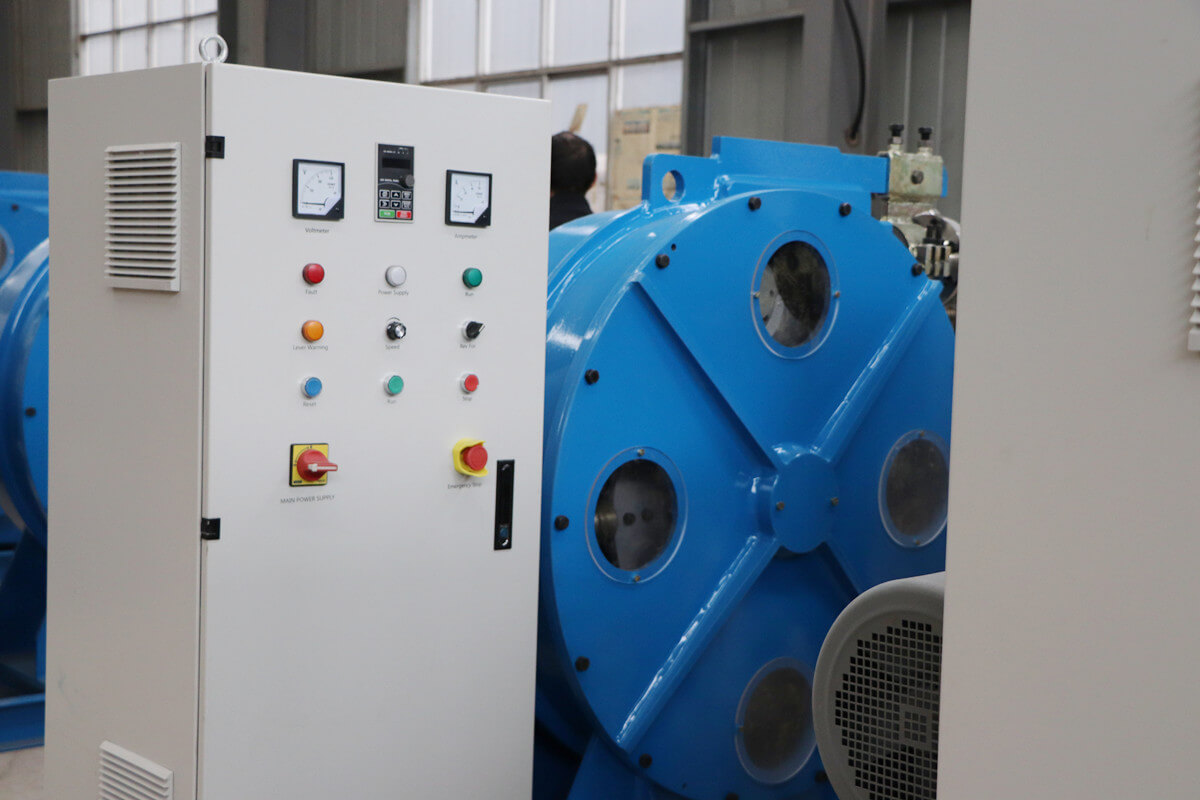

Nowadays, with continuous updates, customers are beginning to use industrial hose pumps to pump lime milk through actual tests and comparisons. This is a new type of technical solution. Squeeze, shrink and restore the hose to achieve the transport effect. There is no leakage during the whole transportation, even if the hose is broken, it can be discharged by self-priming. It can also be undone without damaging effects that many chemical pumps cannot achieve. The magic of the hose disturbing the pump lies in the hose of the pump body. The service life of the hose has nothing to do with the chemical nature of the medium. The entire pump can be maintained using only the hose, and by quickly replacing the hose, the hose can be restored in time without affecting the process. It is easy to replace and can be replaced by all on-site personnel. The fiber reinforced layer in the center of the hose is the most unique design, which can more disperse the stress and extend its service life. The choice of NR, NBR and other materials determines the necessity of hose pumps to solve many process problems.

In the end, the customer replaced all the rotor pumps with hose pumps by comparing the two production lines and cost estimates. Hose pumps are highly praised by customers in the transportation of lime milk. The emergence of hose pumps provides a solution for pumping a variety of substances. So far, hose pumps have been used in many industries, including beer, beverage, sewage treatment and chemical industries, and have been recommended and recognized by many customers.