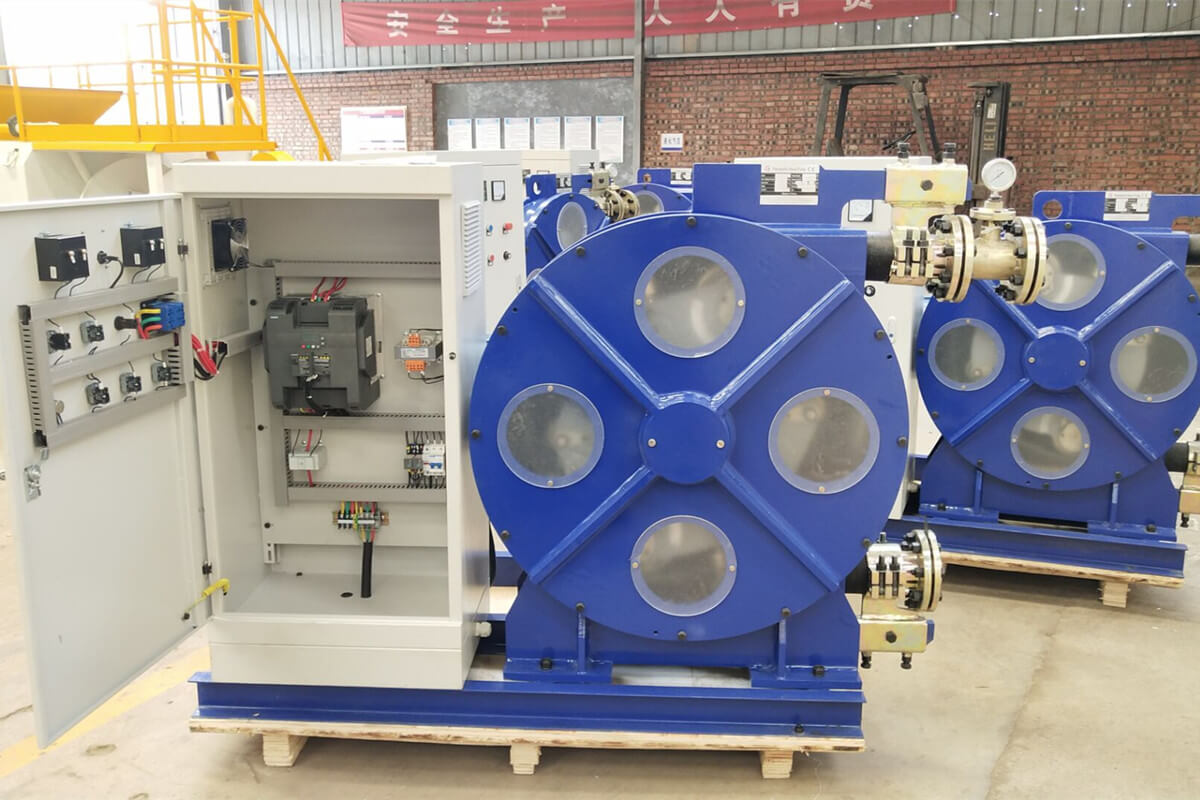

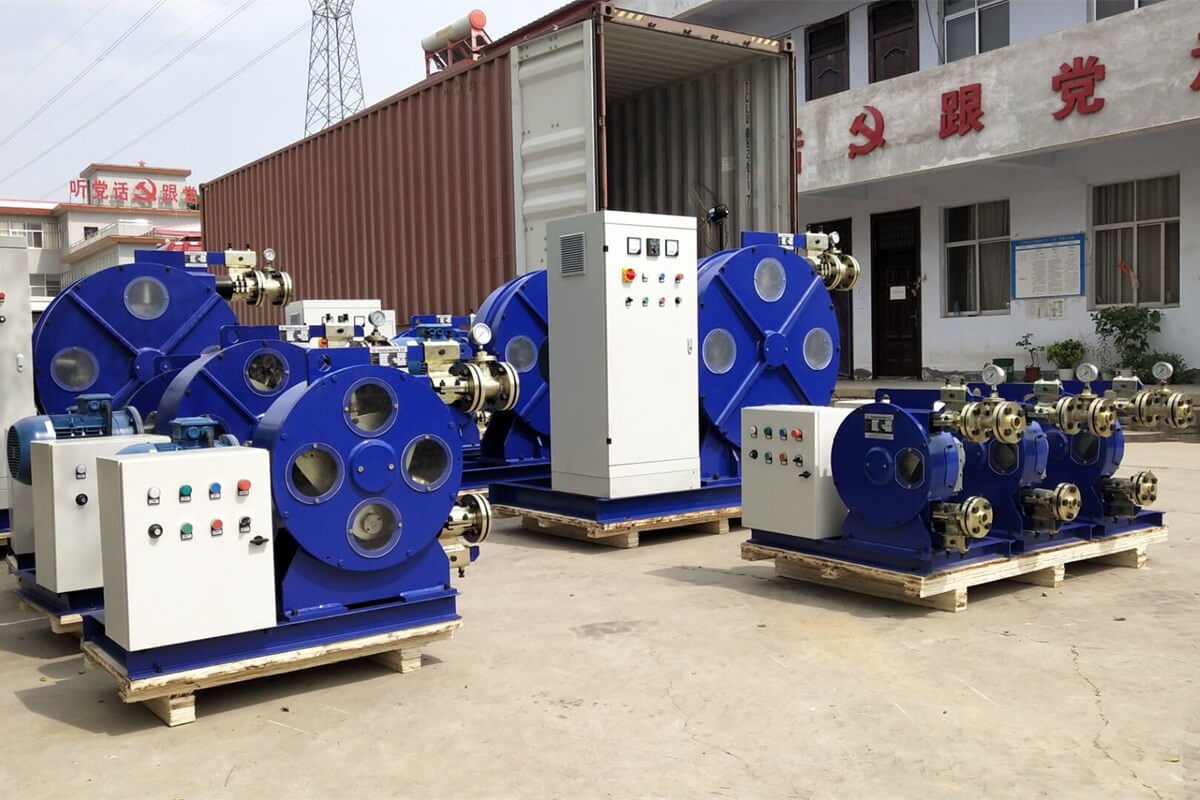

Hose pump is also know as peristaltic pump, having wide applications. Compare with other kind pumps, peristaltic hose pump for pumping mining slurry structure is very simple. Squeeze hose is U-Shape in the pump house, while rotor drives roller to rotate, hose is deformed. After the roller rotate, the deformed hose recover by its elasticity. Thus the negative pressure in this hose is generated, suicking slurries, and dischargeing through oulet under roller's push, finally forms pressure conveying of slurries.

Different Hose Pump Pump Core Structure

Peristaltic hose pump is be divided into roller structure and pressure shoe structure according to different squeeze method. Most of our hose pump adopts roller structure, different with foreign pressure shoe structure hose pumps. Roller structure hose pump, rolling friction is generated between roller and squeeze hose, while pressure shoe structure, sliding friction is generated between pressure shoe and squeeze hose. As far as we know, under same press, rolling friction is smaller than sliding friction, so roller structure is more friendful for squeeze hose, helpful to extend the service life of squeeze hose.

More important, to reduce the friction, pressure shoe structure need add lubricating oil in the pump house, while roller structure hose pump, don't need add lubrication oil in the pump house. For this reason, the roller structure hose pump is very suitable for outdoor or harsh working conditions.

On the other hand, our peristaltic hose pump for pumping mining slurry adopt K series helical bevel gearbox, heavy load, high resistance to overload than cycloidal pinwheel reducer gearbox.

In short, peristaltic hose pump for pumping mining slurry are also very suitable for pumping the following materials: