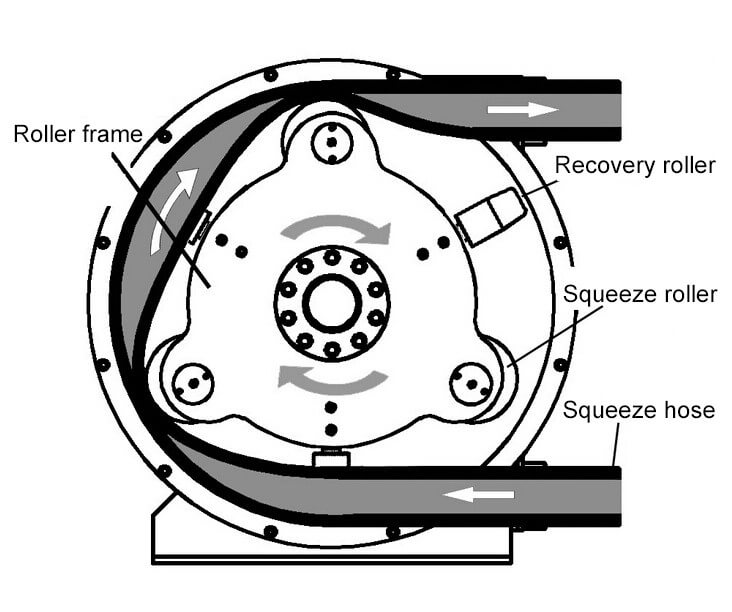

The hose pump is called a peristaltic pump and works like the human digestive peristaltic system. Usually industrial hose pumps are mainly composed of pump chamber, rotor, idler, idler roller, squeeze hose and drive unit.

Hose pump working principle:

Usually, a special rubber hose with a smooth inner wall and a particularly good strength is installed inside the pump body and then rotated by a pair of press rolls along the hose. This rotation causes the medium to be transported in one direction without There is a reverse flow, after the hose is transported, the hose is restored to its original state by the self-elasticity of the pressurized hose and the side guide roller. At this time, a high vacuum is generated in the hose to suck the medium into the lumen again; then the medium is The accompanying press rolls are squeezed out of the hose. As a result of this cycle, the medium is continuously discharged and inhaled.

Hose pump features:

1. Self-priming ability, can run dry

2. Except for the pump tube, the fluid does not come into contact with any part of the pump;

3. Can pump liquid, gas, solid or multiphase mixture

4. From the inlet to the exit can use a complete pump tube, no seams, no valves

5. Quick replacement of the product only need to replace the pump tube - to avoid cross-infection;

6. Easy installation, simple operation, easy cleaning and low maintenance cost;

7. Can be applied to multi-channel pumping occasions.

8. The flow adjustment range is large, easy to control, can achieve timing, constant, variable transport, because of the memory ability, can ensure good reproducibility;

9. Can pump shear sensitive, viscous, organic and inorganic solvents and corrosive liquids;